Buffing Process In Manufacturing . in the manufacturing industry, polishing and buffing are two common finishing methods. They both involve smoothing the surface of a workpiece to. It can be done by using an angle grinder with. It's essential to understand the principles of polishing and. buffing is a surface finishing process employed to shine wood, metal, or composites utilizing a wheel made from cotton. the objective of bufing and polishing is to make a rough surface into a smooth one and, of course, each work piece will be in a different. buffing is a process of removing any lines or abrasives in stainless steel and making it more luster or shinier. It levels out the residues or excess products to provide a smooth surface. buffing is a surface finishing process to shine metal, wood, or composites. buffing and polishing are two common finishing processes used in the manufacturing industry.

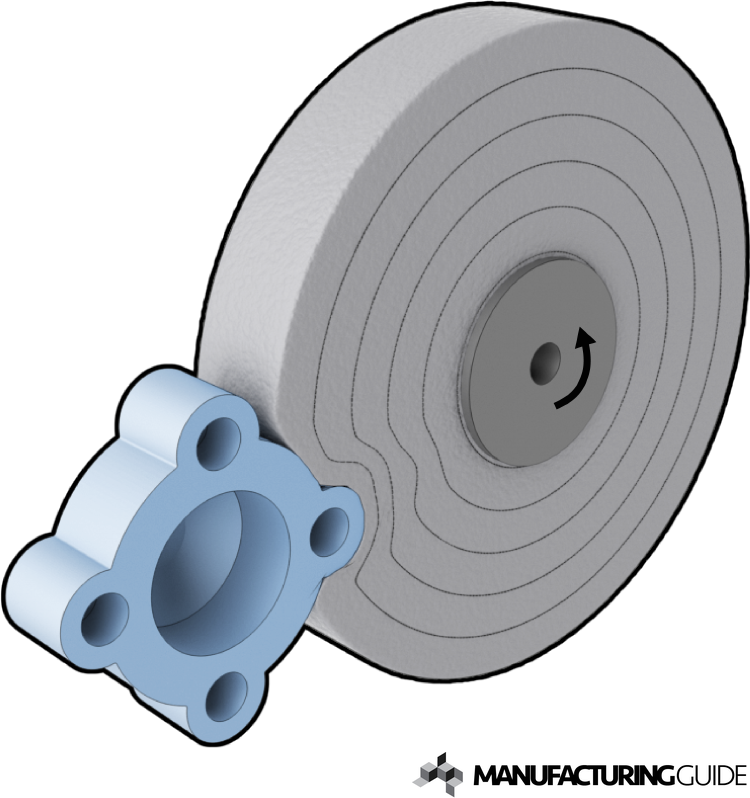

from www.manufacturingguide.com

buffing and polishing are two common finishing processes used in the manufacturing industry. buffing is a process of removing any lines or abrasives in stainless steel and making it more luster or shinier. the objective of bufing and polishing is to make a rough surface into a smooth one and, of course, each work piece will be in a different. It levels out the residues or excess products to provide a smooth surface. buffing is a surface finishing process to shine metal, wood, or composites. buffing is a surface finishing process employed to shine wood, metal, or composites utilizing a wheel made from cotton. They both involve smoothing the surface of a workpiece to. in the manufacturing industry, polishing and buffing are two common finishing methods. It's essential to understand the principles of polishing and. It can be done by using an angle grinder with.

Buffing Find suppliers, processes & material

Buffing Process In Manufacturing the objective of bufing and polishing is to make a rough surface into a smooth one and, of course, each work piece will be in a different. in the manufacturing industry, polishing and buffing are two common finishing methods. the objective of bufing and polishing is to make a rough surface into a smooth one and, of course, each work piece will be in a different. They both involve smoothing the surface of a workpiece to. buffing and polishing are two common finishing processes used in the manufacturing industry. It's essential to understand the principles of polishing and. buffing is a surface finishing process to shine metal, wood, or composites. It levels out the residues or excess products to provide a smooth surface. buffing is a surface finishing process employed to shine wood, metal, or composites utilizing a wheel made from cotton. buffing is a process of removing any lines or abrasives in stainless steel and making it more luster or shinier. It can be done by using an angle grinder with.

From www.youtube.com

Buffing Stainless & Aluminum to a Mirror Finish from Eastwood with the Buffing Kit YouTube Buffing Process In Manufacturing buffing and polishing are two common finishing processes used in the manufacturing industry. They both involve smoothing the surface of a workpiece to. in the manufacturing industry, polishing and buffing are two common finishing methods. the objective of bufing and polishing is to make a rough surface into a smooth one and, of course, each work piece. Buffing Process In Manufacturing.

From www.horiba.com

化学机械研磨(CMP) HORIBA Buffing Process In Manufacturing It levels out the residues or excess products to provide a smooth surface. It can be done by using an angle grinder with. They both involve smoothing the surface of a workpiece to. buffing is a process of removing any lines or abrasives in stainless steel and making it more luster or shinier. buffing and polishing are two. Buffing Process In Manufacturing.

From www.dreamstime.com

The Engineer Program Robotic Arm for Polishing Automotive Parts. Stock Photo Image of Buffing Process In Manufacturing It levels out the residues or excess products to provide a smooth surface. buffing is a surface finishing process employed to shine wood, metal, or composites utilizing a wheel made from cotton. buffing is a process of removing any lines or abrasives in stainless steel and making it more luster or shinier. It's essential to understand the principles. Buffing Process In Manufacturing.

From dangstars.blogspot.com

Standard Operation Procedured (SOP) Dangstars™ Buffing Process In Manufacturing buffing is a process of removing any lines or abrasives in stainless steel and making it more luster or shinier. buffing and polishing are two common finishing processes used in the manufacturing industry. It can be done by using an angle grinder with. in the manufacturing industry, polishing and buffing are two common finishing methods. the. Buffing Process In Manufacturing.

From www.manufacturingguide.com

Buffing Find suppliers, processes & material Buffing Process In Manufacturing buffing is a surface finishing process to shine metal, wood, or composites. the objective of bufing and polishing is to make a rough surface into a smooth one and, of course, each work piece will be in a different. buffing is a surface finishing process employed to shine wood, metal, or composites utilizing a wheel made from. Buffing Process In Manufacturing.

From formaxmfg.com

A Word About Buffing Formax Manufacturing Buffing Process In Manufacturing buffing is a process of removing any lines or abrasives in stainless steel and making it more luster or shinier. buffing is a surface finishing process to shine metal, wood, or composites. buffing is a surface finishing process employed to shine wood, metal, or composites utilizing a wheel made from cotton. It can be done by using. Buffing Process In Manufacturing.

From www.youtube.com

Buffing YouTube Buffing Process In Manufacturing buffing is a surface finishing process to shine metal, wood, or composites. It levels out the residues or excess products to provide a smooth surface. buffing is a process of removing any lines or abrasives in stainless steel and making it more luster or shinier. They both involve smoothing the surface of a workpiece to. in the. Buffing Process In Manufacturing.

From www.youtube.com

Buffing Process (हिन्दी ) YouTube Buffing Process In Manufacturing It can be done by using an angle grinder with. the objective of bufing and polishing is to make a rough surface into a smooth one and, of course, each work piece will be in a different. They both involve smoothing the surface of a workpiece to. buffing is a process of removing any lines or abrasives in. Buffing Process In Manufacturing.

From www.slideserve.com

PPT What is Buffing Process PowerPoint Presentation, free download ID11087183 Buffing Process In Manufacturing buffing is a surface finishing process to shine metal, wood, or composites. in the manufacturing industry, polishing and buffing are two common finishing methods. It can be done by using an angle grinder with. the objective of bufing and polishing is to make a rough surface into a smooth one and, of course, each work piece will. Buffing Process In Manufacturing.

From themechanicalengineering.com

Buffing and Polishing Process Definition, Advantages, Disadvantages, Application, Differences Buffing Process In Manufacturing It levels out the residues or excess products to provide a smooth surface. buffing and polishing are two common finishing processes used in the manufacturing industry. in the manufacturing industry, polishing and buffing are two common finishing methods. They both involve smoothing the surface of a workpiece to. It can be done by using an angle grinder with.. Buffing Process In Manufacturing.

From www.youtube.com

Doorito SS Towerbolt Manufacturing Process Jamnagar Towerbolt Machine Buffing Process Buffing Process In Manufacturing buffing is a process of removing any lines or abrasives in stainless steel and making it more luster or shinier. They both involve smoothing the surface of a workpiece to. the objective of bufing and polishing is to make a rough surface into a smooth one and, of course, each work piece will be in a different. . Buffing Process In Manufacturing.

From www.alamy.com

Process Of Buffing Leather Hides On A Industrial Machine, Manufacturing Stock Video Footage Alamy Buffing Process In Manufacturing It levels out the residues or excess products to provide a smooth surface. the objective of bufing and polishing is to make a rough surface into a smooth one and, of course, each work piece will be in a different. It can be done by using an angle grinder with. in the manufacturing industry, polishing and buffing are. Buffing Process In Manufacturing.

From www.slideserve.com

PPT What is Buffing Process PowerPoint Presentation, free download ID11087183 Buffing Process In Manufacturing buffing is a surface finishing process employed to shine wood, metal, or composites utilizing a wheel made from cotton. It's essential to understand the principles of polishing and. in the manufacturing industry, polishing and buffing are two common finishing methods. It levels out the residues or excess products to provide a smooth surface. the objective of bufing. Buffing Process In Manufacturing.

From www.scribd.com

Buffing Process in Manufacturing PDF Abrasive Chemistry Buffing Process In Manufacturing in the manufacturing industry, polishing and buffing are two common finishing methods. buffing is a process of removing any lines or abrasives in stainless steel and making it more luster or shinier. buffing is a surface finishing process to shine metal, wood, or composites. They both involve smoothing the surface of a workpiece to. buffing is. Buffing Process In Manufacturing.

From southhavenfinishing.com

Metal Finishing Capabilities South Haven Finishing Buffing Process In Manufacturing It levels out the residues or excess products to provide a smooth surface. in the manufacturing industry, polishing and buffing are two common finishing methods. It can be done by using an angle grinder with. They both involve smoothing the surface of a workpiece to. buffing is a surface finishing process employed to shine wood, metal, or composites. Buffing Process In Manufacturing.

From www.linkedin.com

[Video] Acme Manufacturing on LinkedIn Robotic DieCast Buffing Process with Dual Multi Head Buffing Process In Manufacturing They both involve smoothing the surface of a workpiece to. It's essential to understand the principles of polishing and. the objective of bufing and polishing is to make a rough surface into a smooth one and, of course, each work piece will be in a different. in the manufacturing industry, polishing and buffing are two common finishing methods.. Buffing Process In Manufacturing.

From www.youtube.com

buffing process YouTube Buffing Process In Manufacturing buffing is a surface finishing process employed to shine wood, metal, or composites utilizing a wheel made from cotton. in the manufacturing industry, polishing and buffing are two common finishing methods. It can be done by using an angle grinder with. It levels out the residues or excess products to provide a smooth surface. buffing is a. Buffing Process In Manufacturing.

From www.youtube.com

Buffing Process YouTube Buffing Process In Manufacturing It can be done by using an angle grinder with. They both involve smoothing the surface of a workpiece to. It levels out the residues or excess products to provide a smooth surface. the objective of bufing and polishing is to make a rough surface into a smooth one and, of course, each work piece will be in a. Buffing Process In Manufacturing.